plug flow reactor equation

We substitute these equations to obtain. Coli100 ml k d 5 hr-1 r c rate of chlorine decay from microorganism Cl-demand -k c X k c 10-5 mg-chlorineL100mL-1hr-1 2 rate expressions 2 constituents 2 coupled mass balances find.

Plug Flow Reactor Overview Youtube

An advantage of the plug flow model is that no part of the solution of the problem can be perpetuated upstream.

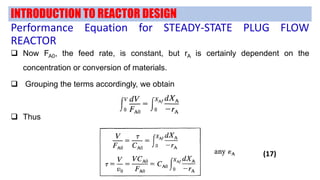

. In a plug flow reactor nutrients and sometimes organisms are introduced to the reactor continuously and move through the reactor as a plug. For steady-state operation of a plug flow reactor the basic design equation equation 829 can be written as. Transient energy balance on a PFR R137-3 This equation must be coupled with the mole balances R137-4 Numerical solution required for these three coupled equations.

The volume of the reactor needed to achieve a final conversion is given by. Gives a plug flow reactor without recycle case has the lowest value. Derivation of the design equation for a plug flow reactor with second order kineticsPresented by Professor Alan Hall University of Huddersfield.

On application of the above to Equation 1 the mass balance on i becomes. WHG 9 Reactor size comparisons for PFR and CSTR. There are two limiting cases.

3 The temperature dependence of the reaction rate r can be estimated using the Arrhenius equation. 4 Types of Multiphase Reactions Gas-liquid without catalyst Gas-liquid with soluble catalyst Gas-liquid with solid catalyst Gas-liquid-liquid with soluble or solid catalyst Gas-liquid. Reactors in series and in parallel.

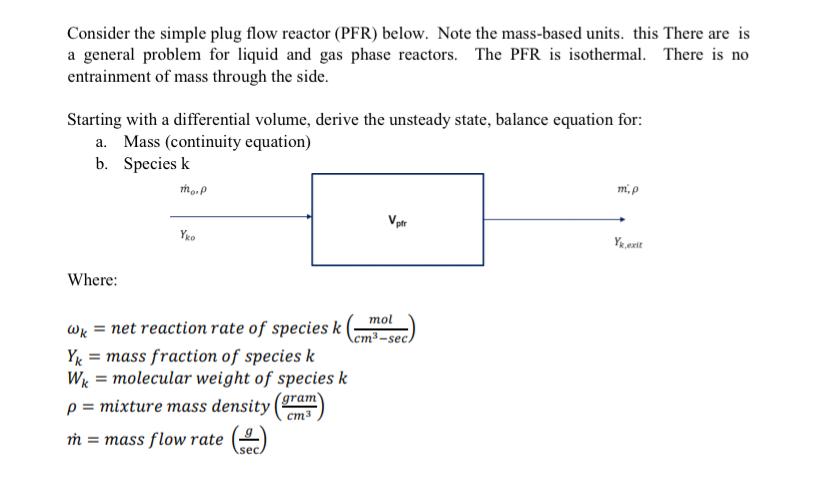

Let us perform a steady-state mass balance on substrate around the section using Eq. Neglecting shaft work and changes in pressure with respect to time we obtain. Beginequation fracdmdt sum_in dotm_in - sum_out dotm_out dotm_wall endequation.

X concentration of microorganisms at any point in contact reactor Xo influent concentration of microorganisms 106 E. Where is the volumetric flow rate V is the reactors volume and is the reactors conversion of species A. Illustrate concepts through use of case studies.

Dv 0 vv dz 0. How choice of reactor affects selectivity vs. The system may be either contained as in a water main oil pipeline or blood vessel or open as in a.

Derive basic reactor performance equations using ideal flow patterns for the various phases. DV area dz Mass flow rate is constant vAρconst. Prepare chemical reaction engineering for GATEESE 2022 Exam with these Complete lectures on chemical reaction engineering wherein Shailendra Sir has covered.

Equations reactor sizing for constant volume and variable volume processes. Combining reactors with separations. To develop equations for a plug flow enzyme reactor we must consider a small section of the reactor of length Δ z as indicated in Figure 1433.

Divide all reaction rates by the velocity return r u for r in reaction_model C model_param define initial values for C and the span for calculation 0 to 1 m where 1 m is the length of the reactor tube C0 06 04 00 span 00 10 solve the problem and plot the solution note how we can pass parameters to the function using the args keyword argument of solve_ivp sol. Reactor volume and flow path length L such. WHG Lecture 6 correction.

We can rewrite the design equation for a plug-flow reactor Equation 2-16 in terms of the concentration C rather than in terms of conversion for the special case when v Vq. Other simplifications used are perfect radial mixing and a homogeneous bed structure. 62 which is the basic form of the design equation for a plug-flow reactor V is the reactor volume G is the total mass flow through the reactor Cao is the concentration of A at inlet in moles per unit mass of feed Xa is the fractional conversion of A.

Plug Flow Reactor PFR The third general type of reactor is the Plug Flow Reactor PFR. V FAO1 R XfRXf 1 RdXA rA where V is the volume of the reactor m 3 FAO is the mass flow rate of the feeding stream kgh R is the recycle ratio Xf is the conversion of products and rA is the kinetic expression of the chemical reaction 9. A reversible reaction takes place in an adiabatic plugflow reactor PFR Select either an exothermic or an endothermic reaction The black curve is the equilibrium conversion as a function of temperature from the vant Hoff equation The blue line is conversion as a function of temperature from the adiabatic energy balance The intersection of the curve and the line is the.

Chemical Reactor is known as the heart of any chemical plant since the new chemicals are produced only in this vessel and the economics of the entire plant depends on the design of reactor. These chemicals are produced through chemical reactions in a vessel called Chemical Reactor. Introduce non-ideal fluid mixing models.

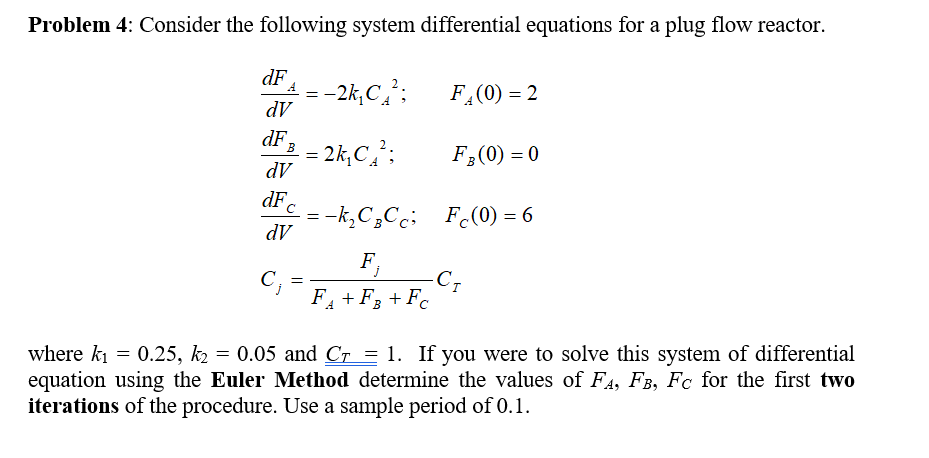

Generally as the temperature increases so does the rate at which the. Chemical Reaction Engineering CRE deals with the design. This results in differential equations that need to be integrated to find the reactor conversion and outlet temperatures.

Diagram of a plug flow reactor showing flow in the z-direction. Reactors do not always run at steady state. ρCWii For a liquid dρ 0 dz dvρA dv dA dρ ρρAvAv0 dz dz dz dz Rearrange.

Dv 11dA dρ v dz A dz ρdz For a normal pipe dA 0 and for a liquid dz dρ 0 dz Therefore. This allows one to calculate the exact solution to the differential. And the rate law R137-5.

In fact many pharmaceuticals are made in a batch mode. This section is located at distance z from the feed point. When like terms are cancelled and the limit dx 0 is applied to Equation 2 the mass balance on species i becomes.

KDW 8 The plug flow reactor. The total mass of the reactors contents changes as a result of flow through the reactors inlets and outlets and production of homogeneous phase species on the reactor walls. Gives mixed flow reactor behavior has the highest value.

Solved 4 20 Points Consider A Plug Flow Reactor As Chegg Com

Plug Flow Reactor Pfr Sizing And Conversion Example Youtube

Mole Balance On A Plug Flow Reactor Youtube

L 2 1 Review What Size Reactors To

Plug Flow Reactor Design Equation Youtube

Plug Flow Reactor With First Order Kinetics Performance Equation Youtube

Computational Scheme For A Plug Flow Reactor Defining The Function Download Scientific Diagram

Solved Consider The Simple Plug Flow Reactor Pfr Below Chegg Com

Answered Problem 4 Consider The Following Bartleby

Cstr Vs Pfr Differences And Performance Equations Youtube

Sizing A Plug Flow Reactor Pfr Youtube

Matlab In Chemical Engineering At Cmu

Introduction To Energy Balances For Plug Flow Reactors Youtube

Isothermal Plug Flow Reactor Part 1 Youtube

Chemical Reaction Engineering Ppt Download

Plug Flow Reactor With Second Order Kinetics Design Equation Youtube